Current challenges

Although high-rate reactions can be achieved in the short term, current alkaline CO₂ conversion technologies struggle to sustain performance over extended operation. The CO₂ reaction with hydroxide ions forms carbonate and bicarbonate (HCO₃⁻), leading to CO₂ losses and requiring higher feed rates to compensate. This also increases energy consumption and causes operational issues that can shorten the electrolyser lifetimes.

What could be the solution?

Acidic CO₂ reduction prevents carbonate formation, which enhances CO₂ utilisation and efficiency, making it more energy-efficient and industrially viable.

Innovation in electrolyser components

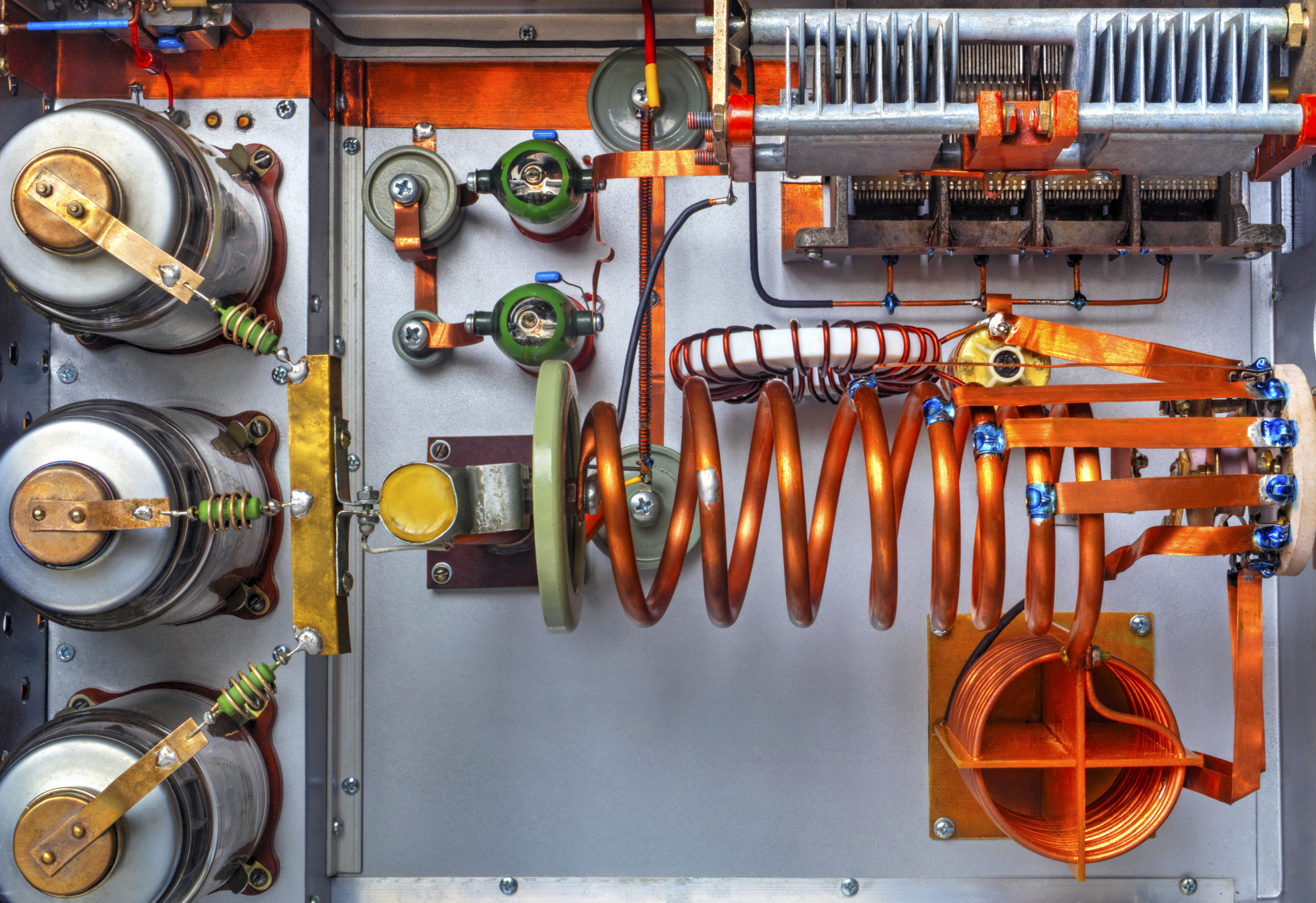

This project aims to develop innovative catalysts that can operate in acidic environments while suppressing the competing hydrogen-evolving reaction. Specifically, it focuses on integrating electrochemically active copper sites with acid-stable components, such as bismuth oxide, to develop durable acid-resistant electrodes.

To achieve this, the research team is using advanced thermal and cold spray coating techniques to fabricate durable and high-performance electrodes. The spray techniques allow for precise control over coating composition, surface roughness and porosity— key factors that influence electrochemical performance. By leveraging the unique spray facilities at SUT and RMUTP, the project will scale up catalyst-coated electrodes to a practical size of 25 cm². These electrodes will serve as critical components in next-generation electrolysers, enabling efficient and selective CO2 reduction at an industrial scale.

Strength in collaboration: SUT Australia and RMUTP Thailand

The success of this project is driven by the complementary expertise of the Chief Investigators and their team members, along with access to advanced high-end facilities at RMUTP and SUT. Associate Professor Rosalie Hocking and Dr Jirasak Tharajak bring expertise in nanomaterials and electrocatalyst characterisation, while Dr Thành Trần-Phú focuses on accelerating electrolyser design and operation. Associate Professor Andrew Ang, Dr Poomirat Nawarat, Dr Surinder Singh, and Dr Duy Quang Pham specialise in advanced manufacturing and thermal spray processes. RMUTP’s state-of-the-art cold spray facilities and SUT’s advanced suspension plasma spray technology play crucial roles in scaling up catalyst-coated electrodes. The project also benefits from in situ characterisation methods, including synchrotron-based X-ray imaging and X-ray absorption spectroscopy, enabled by the Australian Synchrotron.

By combining cutting-edge facilities, interdisciplinary expertise and strong international collaboration, this project aims to revolutionise electrolyser technology, strengthening Australia’s and Thailand’s positions as leaders in the clean energy transition.

Benefits

This collaboration between Australia and Thailand offers significant national and international benefits, strengthening professional linkages with global institutions like RMUTP. It grants Australian researchers access to cutting-edge cold spray and electrochemical technologies while fostering economic growth through scalable CO2 electrolysers. Additionally, advancements in catalyst stability and electrode engineering will drive innovation in energy conversion technologies.

Towards commercialisation and impact

Beyond fundamental research, this collaboration is committed to scaling innovations for commercial deployment. By optimising fabrication processes, the team aims to produce robust, cost-effective electrolyser components ready for market integration.

By leveraging cutting-edge research, advanced manufacturing and international collaboration, the Australia-Thailand Electrolyser Component Manufacture project is set to drive significant progress in green chemistry and industrial decarbonisation. This partnership not only strengthens bilateral ties but also paves the way for innovative solutions in the global clean energy transition.